Railveyor’s innovative material handling system reduces costs over 90%*

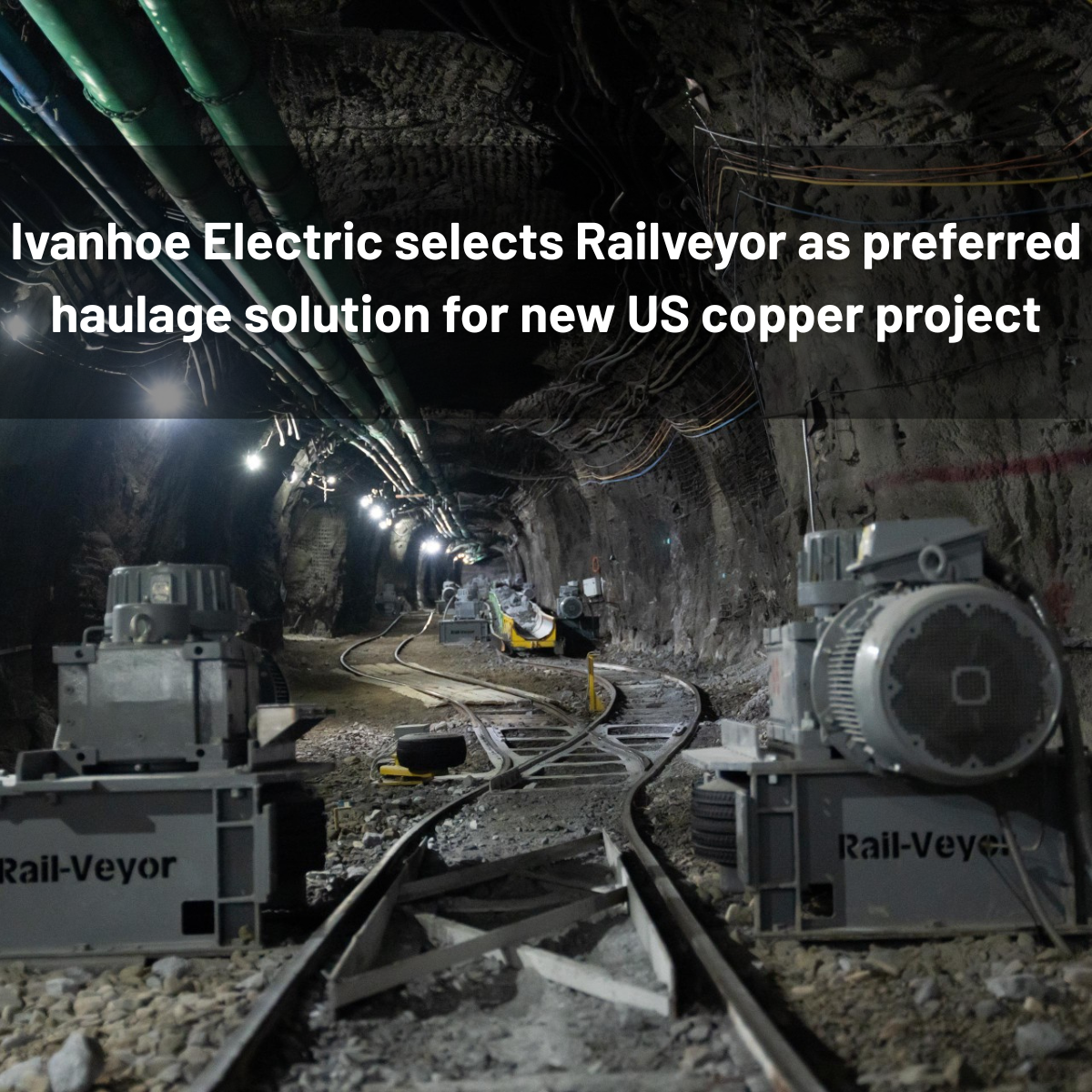

Composed of a light rail train propelled by stationary drive stations, Railveyor is controlled and optimized by our automation software. Unlike competing haulage systems, the Railveyor system is fully electric and TrulyAutonomous – no dedicated operator required. Designed from first principles leveraging the best of 21st century technology, Railveyor is now beating traditional haulage systems around the world – transporting material with less emissions, enhanced safety and strikingly improved profitability.

See What Drives Railveyor