NEWS ARTICLE

Releasing “Materials Transport: Racing to Net Zero” Emissions Tradeoff Study

Update Nov. 11, 2022: Please watch the video below as Amber Bieg of Warm Springs Consulting describes the highlights of the study and shares why she’s excited about Railveyor.

Railveyor is the safe, clean and profitable material haulage solution for the mine of the future. That’s a statement that we at the Railveyor company believe to be true – and the benefits of improved worker safety, enhanced productivity and reduced emissions of our TrulyAutonomous system are being proven daily in installations across the globe. Common sense, customer anecdotes and internal analysis have shown us clearly that Railveyor holds a significant advantage over competing haulage systems in terms of reduced greenhouse gas (GHG) emissions.

And now we are pleased to announce that the GHG emissions of Railveyor and competing material transport systems have been analyzed by internationally recognized sustainability consulting firm, Warm Springs Consulting, LLC. Across a number of different metrics, the data shows that Railveyor is truly the industry leading solution when it comes to minimizing GHG emissions. And because Railveyor offers minimal GHG emissions across all Scopes through many years of operation, we believe the TrulyAutonomous system is a game changer in the “race to net zero” in the mining industry.

Key Findings

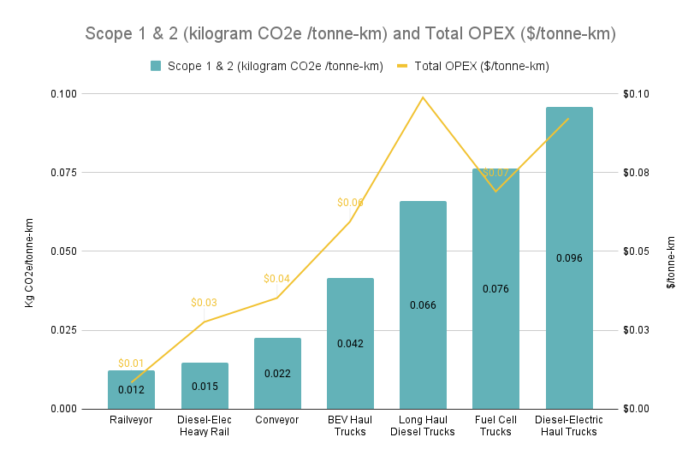

The study highlights several comparisons where Railveyor outperforms the competition. The following chart compares GHG emissions per tonne-km and Total operating expense (OPEX) for several material transport systems.

According to Warm Springs:

Diesel-electric haul trucks are estimated to have the highest GHG emissions of the specified hauling methods at 0.096 kilograms CO2e /tonne-km. This is directly related to the high emissions factor of diesel fuel and limited haul capacity per truck. The hauling method with the lowest emissions is the Railveyor system, with an estimated 0.012 kilograms CO2e /tonne-km.

Based on average diesel and electricity prices, the hauling method with the highest fuel operating cost is estimated to be diesel-electric haul trucks at $0.043 /tonne-km. Railveyor is estimated to have the lowest fuel operating cost at just $0.003 /tonne-km. The hauling method with the highest operating cost not including fuel cost is estimated to be long haul diesel trucks at $0.069 /tonne-km. The lowest non-fuel operating cost is estimated to be Railveyor at $0.005 /tonne-km. (emphasis ours)

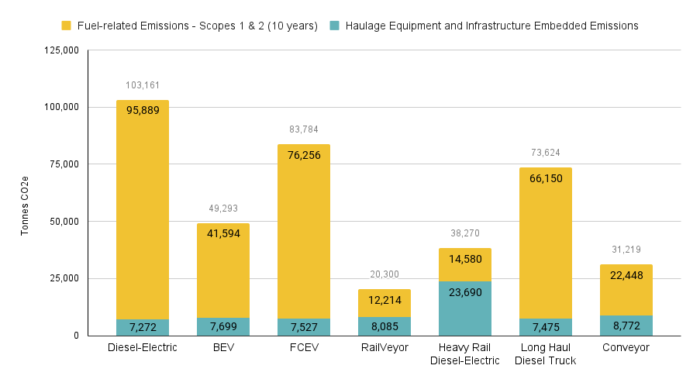

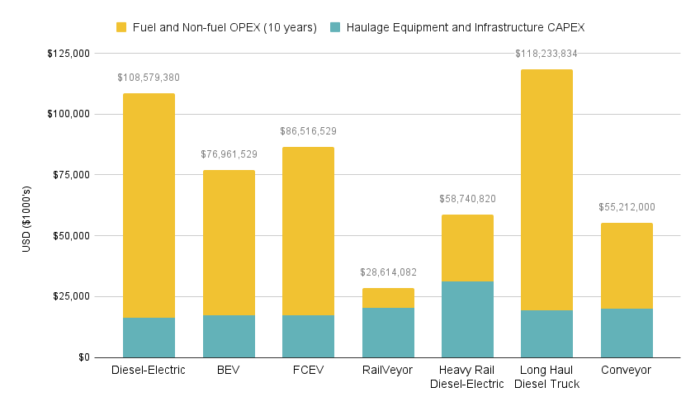

Furthermore, a theoretical scenario of a mine hauling ten millions tonnes per year over 10km was conceived as a practical and comprehensive way to compare both emissions and cost.

Railveyor exhibits dramatically lower Fuel-related Emissions (Scopes 1 & 2) over the ten year period of this scenario and also offers comparable Haulage Equipment and Infrastructure Embedded Emissions (Scope 3) to material transport solutions involving vehicles, which may often be perceived as lower in required infrastructure (and resultant embedded emissions) than they actually are.

In this basic theoretical scenario, the significantly reduced Scope 1 & 2 GHG emissions correlate with a factor that Railveyor’s customers are well acquainted with – Railveyor proves once again that the TrulyAutonomous system offers dramatically reduced OPEX over the life of the system versus competing material haulage solutions.

Another valuable way of looking at the benefits of Railveyor is further within the full study: two Case Studies that utilize trade-off studies of real world mining applications. The “Ring of Fire” project in Northern Ontario compares Railveyor, heavy rail and long haul trucks with respect to emissions, CAPEX/OPEX and even soil disturbance and indigenous issues. Many of these emerging issues and the specific benefits that Railveyor brings to customers focused on improving ESG outcomes across their operations will be explored in future content available on railveyor.com

Thanks to Warm Springs Consulting for their excellent work in compiling the research and analysis available in the study. We encourage those in the mining industry to peruse the study, knowing that the team at Railveyor would be happy to answer any questions that you might have. Reach out today via the Contact page and join Railveyor in the race to net zero.